Hệ thống quản lý kho hàng WMS là gì? Giải đáp toàn bộ về WMS

A WMS, or warehouse management system, is software that helps companies manage and control daily warehouse operations, from the moment goods and materials enter a distribution or fulfilment centre until the moment they leave.

WMS software systems are a key component of supply chain management and offer real-time visibility into a company’s entire inventory, in warehouses and in transit. In addition to inventory management, a WMS offers tools for picking and packing processes, resource utilisation, analytics, and more.

Why is WMS important?

Now more than ever, wholesalers, third-party logistics (3PL) providers, and shippers are under pressure to fulfil and deliver omnichannel orders at the speed of Amazon. E-commerce sales have also surged.

In 2019 alone, Statista reports that U.S. online retail sales amounted to US$343.15 billion – and they’re projected to reach almost $476.5 billion by 2024. While online sales and expectations for fast shipping are growing, the labour pool is shrinking. And until the COVID-19 pandemic took hold in mid-March of 2020, a low national unemployment rate made it difficult to find warehouse workers. Although the number of available workers is temporarily higher, post-COVID-19 warehouse labour will likely be scarce once again. These forces all create the need for faster, more efficient warehouse management and logistics processes.

A good WMS system can help by streamlining every facet of warehouse management – from receiving, put-away, and pick, pack, and shipping processes to inventory tracking and replenishment.

It organizes all of these activities from a single interface. Warehouse management systems also integrate with other tools, including basics like bar code scanning and RFID labelling, more advanced robotics and augmented reality (AR) wearables, and other mission-critical solutions, such as transportation management systems (TMS), ERP, and logistics software.

3 main types of WMS software

Standalone WMS

These systems are usually deployed on the company’s own premises using their own hardware.

They can generally support greater customization (though these can be costly) and the organization can maintain tighter control over their data and software. Although the initial cost of the system is substantially higher than other options, once a company owns it, they own it. At the same time, updates, maintenance, and the costs associated with them are the responsibility of the organization. As the WMS ages, it becomes increasingly difficult to integrate with other platforms and to implement new technologies.

Cloud WMS

Cloud-based WMS systems can be rapidly deployed with lower up-front costs. Delivered as software-as-a-service (SaaS), they provide more flexibility to support seasonal and other changing market conditions – and they are easier to scale as companies grow. Through regular updates, warehouse management in the cloud offers a quicker path to innovation. And someone else takes on the burden of maintaining and updating the system.

SaaS vendors also invest a lot of money and expertise into security measures and provide disaster recovery capabilities. Cloud warehouse management systems can also be more easily integrated with other solutions.

Integrated ERP and SCM-based WMS

Some warehouse management systems are built as modules or applications that integrate with ERP and supply chain platforms.

The advantage of these is that they are able to play better with other solutions in overlapping areas, such as accounting and business intelligence. They provide a holistic view across the business and logistics chain to allow for end-to-end transparency and for warehousing and logistics processes to be orchestrated and executed together. Ultimately these capabilities can be used to optimise operations and provide fast, agile fulfilment experiences.

Core features of a WMS (Warehouse Management System)

Receiving and put-away process

A WMS can help companies receive, process, and put away items in the most efficient way based on business rules and warehouse flow.

A WMS system supports using RFID technology and integration with billing and other software so that items can be automatically received, validated, and reconciled against digital purchase orders with the scan of a barcode, and with labels printed for easier storage and retrieval.

Inventory management

Warehouse management software provides real-time visibility into an organization's inventory across any location, including items in transit and in stores. It provides tracking information using automatic identification and data capture (AIDC) technology such as barcodes or RFID. And many systems support cycle counting and demand forecasting using advanced analytics and insights into product and vendor performance. With these insights, companies can adjust inventory levels on the fly to ensure there’s just enough stock to satisfy customer demand, whether in-store or online.

Accurate inventory tracking and other practices are key to improving order rates – meaning orders that arrive complete, on time, undamaged, and with an accurate invoice. They can also help allocate inventory according to custom workflows and picking logic so that inventory can be moved faster, both into and out of the warehouse.

Order picking, packing, and fulfilment

The most commonly cited place for packing and fulfilment activities is in the warehouse, according to a Logistics Magazine survey. And ResearchGate estimates that the costs related to order picking make up 55% of the total cost of warehousing.

WMS systems can help lower these costs by guiding the most efficient way to store, retrieve, and pack products. They also support picking technologies that streamline the process, such as radio frequency (RF) with and without scanning verification, pick-to-light and pick-to-voice technology, robotics, and algorithms that can help optimize picking paths.

Shipping

Many warehouse systems integrate with transportation management and logistics software that allows for myriad ways to expedite the fulfilment process – generating bills of lading, packing lists, and invoices for shipments automatically, for example, as well as sending out automatic shipment notifications. With real-time tracking features, companies can keep tabs on whether packages arrive on time and to the correct destination.

Labour management

Getting insights into labour-related costs and productivity can help warehouses run leaner, more efficient operations. A WMS can provide real-time visibility into warehouse workers, labour costs, response times, productivity gaps, trends to plan, and more – so companies can react accordingly.

Besides providing key insights, many systems also support task interleaving based on factors such as priority or proximity to help minimise workers’ overall travel time as well as “deadheading” or wasted time. They can also help with planning and scheduling, either directly or through integration with other systems.

Warehouse metrics and analytics

Real-time data can be automatically collected through a WMS instead of relying on manual data collection methods, eliminating keying errors and drastically speeding up the process. This data can also be integrated with analytics to track important metrics, such as on-time shipping, inventory accuracy, distribution costs, order or line fill rate, order cycle time, and more.

The system can then create visual reports that can be easily shared to stakeholders and be used to make adjustments.

How long does it take to implement WMS software?

The timeframe for implementation varies according to how large and complex your warehouse is. If you use a ready-made package, you can get started within a few hours.

If you go for custom WMS software, implementation can take much longer. The whole process can take anywhere between 3 days to several months. Implementation of custom WMS software always starts with an inventory of the processes. A consultant will often visit your company to help you with this, and it serves as the basis for writing a project plan.

Next, the principal user is trained to work with the software, before this person goes on to train their colleagues. The principal user needs to process the master data in order to personalise and populate the WMS software. Links to other systems are implemented and activated.

Benefits of a warehouse management system

Improved operational efficiency

WMS systems automate and streamline warehouse processes from inbound receipts to outbound deliveries – for improved efficiency, smoother operations, and the ability to handle higher volumes. They reduce errors in picking and shipping goods and eliminate duplicate and unnecessary work.

A WMS also shares data with ERP and transportation management systems, giving you a holistic outlook that extends beyond your warehouse and helps expedite the movement of goods.

Reduced waste and costs

If you have date-restricted or perishable stock, WMS software can identify which items need to be picked first, or which might need a sales push, to minimise waste. It can also help you determine the most effective use of warehouse space, from inventory placement to optimal travel paths. Some systems offer advanced simulations to create floor plans and place pallets, shelves, and equipment in the best locations to run at peak efficiency and save time and money.

Real-time inventory visibility

Using barcoding, RFID tagging, sensors, or other location tracking methods, a WMS system gives you real-time insight into your inventory as it moves into your warehouse, around it, and on to the next location. With this visibility, you can create more accurate demand forecasts, run a just-in-time inventory strategy, and improve traceability – which is especially important in the event of a recall.

Improved labour management

A WMS can help you forecast labour needs, create schedules, optimise travel time within a warehouse, and assign the right task to the right employee based on skill level, proximity, and other factors. A good WMS system can also assist in boosting employee morale by creating a more relaxed, organised, and safe environment where workers feel their time is valued and being used wisely.

Better customer and supplier relationships

With a WMS, customers enjoy improved order fulfilment, faster deliveries, and fewer inaccuracies – which increases their satisfaction and loyalty and improves your brand reputation. Suppliers can also experience reduced wait times at loading bays and docks, for improved relations.

Smart warehousing technology

Warehouse automation

Automation technologies are having a significant impact on warehouses and distribution centres. Warehousing workflows and processes that can be streamlined through automation include data collection, barcoding, scanning, picking and packing, shipping, and inventory tracking. This automation makes it possible to operate much more efficiently and scale to changing demand. It also cuts down on human errors such as keying in the wrong shipping address or SKU.

Voice-picking technology

Voice picking, also known as voice-directed warehousing and pick-by-voice, allows operators to carry out tasks and communicate when they’ve been completed without having to use paper or their hands and eyes. Operators use a voice-picking device, usually a voice headset or a voice-dedicated terminal, to receive spoken instructions from the WMS system about where and when to pick incoming orders. Workers can use everyday language to send real-time updates to the warehousing system, including when batches are completed.

Mobile devices

Frontline warehouse workers depend on mobile devices to do their jobs more efficiently. A WMS that can support integration with these technologies is critical.

AI and internet of things (IoT) in warehouse management

Artificial intelligence and the IoT are being increasingly folded into warehouse operations. They promise to help businesses respond dynamically to rapidly changing warehousing conditions instead of having to follow pre-defined rules.

IoT data flows into the WMS from myriad locations, including from material handling equipment such as conveyors, smartphones and handheld devices, passive radio beacons, RFID, and more. AI systems take this data and transform it into usable insights, such as trends, predictive models, and other algorithms that help businesses make important decisions based on current conditions. These technologies can be put to work to help manage routing and labour movement, batch orders, slot inventory dynamically, and much more.

Warehouse robots

Robots that operate in warehouses rely on AI and machine learning to make decisions based on input from their surroundings.

By using a combination of video, audial, thermal, and haptic sensors, robots can measure ambient temperature and even perceive touch. If integration is supported, WMS software directs their activities.

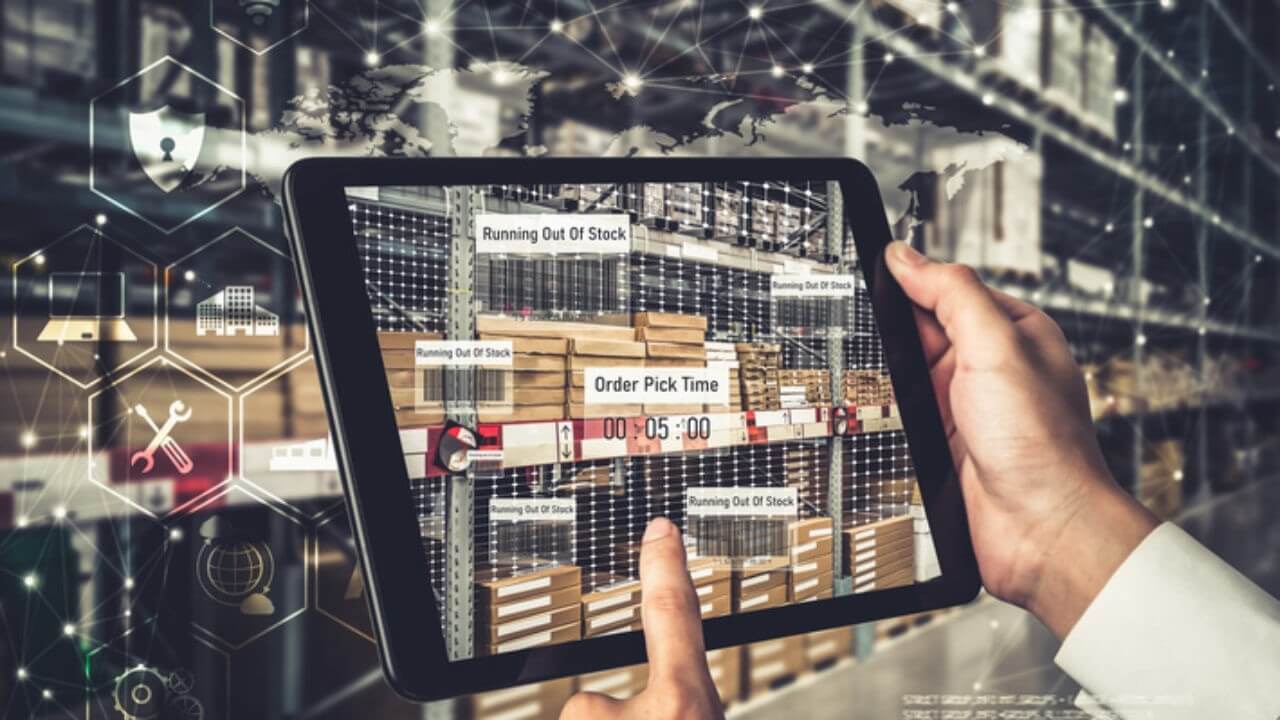

Augmented and virtual reality apps

Augmented reality (AR) technology involves using a camera to capture a real environment, such as an aisle in a warehouse, and then overlays instructions or information on that environment – on a mobile device. AR smart glasses, for example, allow operators to carry out tasks without using their hands. These apps can map out routes, show where bins are located, and more. Virtual reality (VR) technologies are also being used for everything from training lift truck operators to making delivery routes safer.