Providing & designing solutions digital transformation of manufacturing

- Comprehensive integration

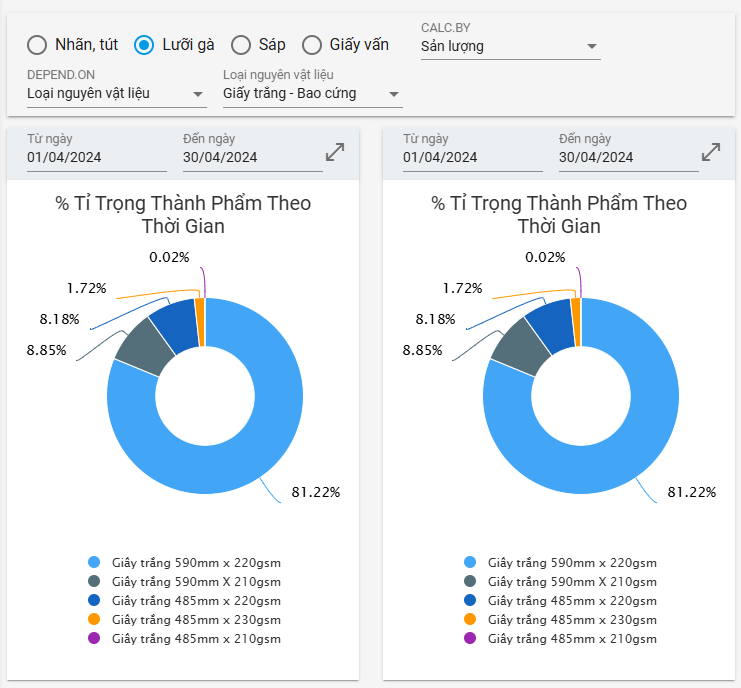

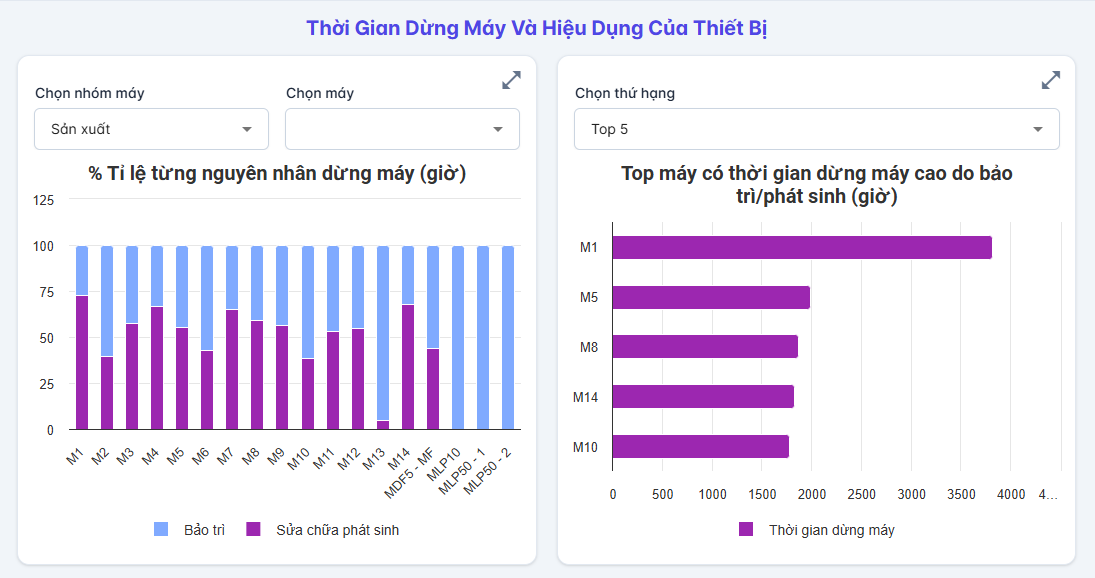

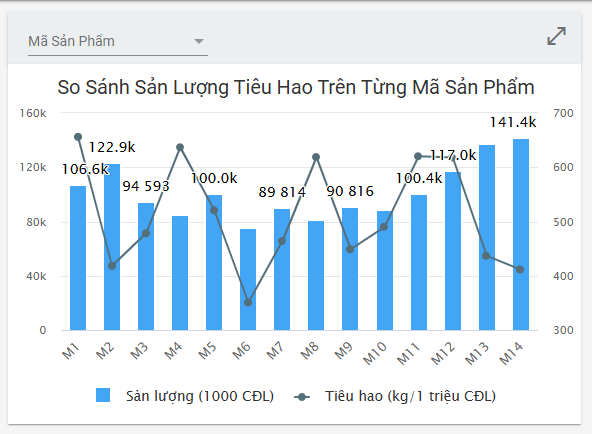

- Visual system

- Optimize performance

Platform solutions DxFACTORY

Applying 4.0 technology to promote performance, reduce operating costs, optimize production resources, and aim for long-term sustainable development.

Optimize warehouse operations and management throughout every stage of the import/export process.

Establish and control product data associated with all stages of production and transportation.

Customer group confident in the DxFACTORY solution

Corporate customers

Production staff

Team management

CEO/Senior Leader

Answering information about DxFACTORY

What is outstanding about the digital transformation solution of manufacturing from DxFACTORY?

Born from New Ocean Group with more than 22 years of operation and development, DxFACTORY solutions benefit from the extensive experience of leading industry experts, a complete product ecosystem and a diverse partner network.

Thanks to that, the DxFACTORY team is always ready to consult and install the system, meeting the need to provide both hardware and software in just one smooth process, saving significant time compared to the traditional way of combining many hardware/software units for single deployment.

Are DxFACTORY products built independently or introduced from outside partners?

All products under the DxFACTORY solution package are designed, refined and completed by the in-house development team from New Ocean Group.

In addition to software system products, New Ocean Group also owns market pioneers in the field of hardware and manufacturing equipment - automation, sensors and visual inspection processing - forming a complete solution ecosystem for manufacturing business owners.

What is the process of implementing the DxFACTORY solution project?

After receiving the information, the DxFACTORY project team will quickly deploy according to standard procedures, including the following basic stages:

- Survey of the current status of production facilities

- Identify project needs & overview project purpose

- Proposed solutions

- Tailor solution categories to exact customer needs

- Quote & agreement before official implementation

Improve production efficiency with DxFACTORY

to new heights

It only takes the equivalent of 2 cups of Starbucks/day & an average of 1-2 weeks for DxFACTORY to start a digital transformation project for manufacturing businesses!

News & professional articles

-

Quản lý sản xuất 2026: 7 lợi ích định lượng của phần mềm MESProduction knowledge

Quản lý sản xuất 2026: 7 lợi ích định lượng của phần mềm MESProduction knowledge -

Nhà Máy Ẩn (Hidden Factory): Tối ưu cho quản lý sản xuấtProduction knowledge

Nhà Máy Ẩn (Hidden Factory): Tối ưu cho quản lý sản xuấtProduction knowledge -

5 hạn chế khi quản lý sản xuất thủ công trong kỷ nguyên 4.0Production knowledge

5 hạn chế khi quản lý sản xuất thủ công trong kỷ nguyên 4.0Production knowledge -

Quản lý sản xuất là gì? Xu hướng trong sản xuất hiện đạiProduction knowledge

Quản lý sản xuất là gì? Xu hướng trong sản xuất hiện đạiProduction knowledge -

Chuyển đổi số thúc đẩy sản xuất bền vững: 5 xu hướng công nghệ cho nhà máy 2026Sản xuất bền vững

Chuyển đổi số thúc đẩy sản xuất bền vững: 5 xu hướng công nghệ cho nhà máy 2026Sản xuất bền vững -

Vòng đời sản phẩm (LCA): Tiếp cận sản xuất bền vữngSản xuất bền vững

Vòng đời sản phẩm (LCA): Tiếp cận sản xuất bền vữngSản xuất bền vững