What is ATO (Assemble-to-Order)? Benefits & Examples of ATO in Manufacturing

Assemble-to-order is a manufacturing strategy under which the manufacturer stocks up on sub-assembly parts and inventories and assembles the parts into the final product when a customer places an order.

It typically requires that the basic parts of the product are already manufactured but not yet assembled. Once an order is received, the parts are assembled quickly and the final product is sent to the customer.

How Assemble-to-Order Works

The assemble-to-order strategy is a hybrid between the make-to-stock strategy (MTS) and the make-to-order strategy (MTO).

- A make-to-stock strategy is one where products are fully produced in advance. The idea is to build an inventory that matches expected or anticipated consumer demand. This method would consist of setting a production level, building up inventory, and then attempting to sell as much assembled product as possible. It's used mostly for high-volume goods, consumables, and items that can be bought in bulk or as a single unit.

- A make-to-order strategy is one where products are manufactured once the order has been received. Production is driven by demand and items are only produced when orders are confirmed. In other words, the supply chain operation does not begin until there is evidence of sufficient customer demand. This strategy is often employed for high-end goods or items made individually or in small batches.

The ATO strategy attempts to combine the benefits of both make-to-order and make-to-stock—getting products into customers' hands quickly while allowing for the product to be adapted or altered in certain ways, as per customer request. Vừa sẵn sàng hoàn thiện sản phẩm nhanh chóng sau khi nhận đơn (chỉ cần lắp ráp các bộ phận đã có sẵn), vừa cho phép sản phẩm được điều chỉnh hoặc thay đổi một phần theo mong muốn của khách.

In most cases, the time and costs associated with building the product from its components are minimal. However, the time and costs to build the components, which are usually ordered from a supplier, can be considerable.

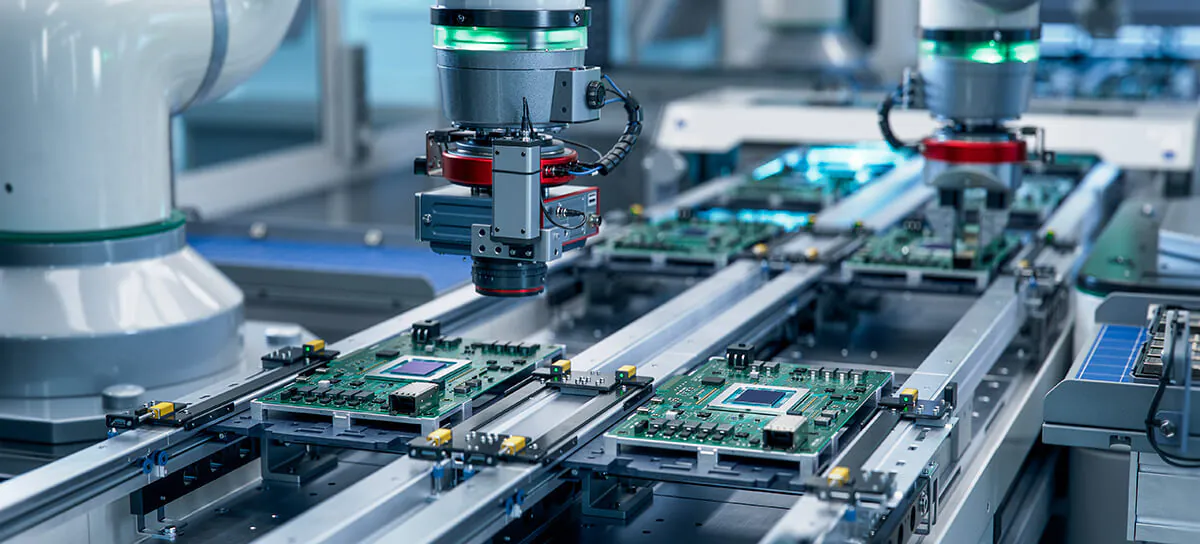

Enabled by technology, advancements in production processes and inventory management systems have played a big part in making assemble-to-order strategies a reality. Add cheaper methods of shipping products, and the strategy has been a boon for product customization opportunities.

ATO Production Process

1. Select products for ATO

Not every product lends itself to the ATO production model. That includes units which:

- Take a long time to assemble

- Take up too much space in your stockroom when fully assembled

- Customers are accustomed to take home instantly

If you’re considering ATO for the first time, handpick a selection of small, quick-to-assemble products to begin with. Expand once your team perfects the process, customers respond well to receiving products later than expected, and demand planning gets more accurate.

2. Break down products into subassemblies

There are various stages of production, and some take much longer than others. Get the best of both worlds by breaking down the production process.

Assemble the time-consuming parts in advance, while finishing the quick-to-assemble items once an order has been placed.

For example, at Paper Crate, the lined pages of the handmade notebooks are made in bulk and stored ready for use. Then, when an order comes in, it's just a case of printing the cover and attaching it to the printed inner pages.

3. Purchase necessary equipment

The faster you can assemble made-to-order products, the quicker each customer receives their order. Equipment can speed up this process.

One example could be barcode scanners that automatically update your inventory management system to provide accurate stock levels when items have been assembled. Or POS technology to notify customers who’ve ordered in-store that their product is ready for collection.

4. Train staff on production processes

If you’re employing a team of retail associates to help run your store, bring them up to speed with production processes. They’ll help you optimize the stockroom and manufacture high-quality products quickly.

Production aside, retail staff need extra training on dealing with customers who are unfamiliar with assemble-to-order products. Role-play the following scenarios to deliver excellent in-store experiences with customers who want their products yesterday:

- Collecting email addresses for products they can’t take home instantly

- Setting customer expectations on order fulfillment times

- Handling “where’s my order?” queries

5. Closely monitor demand

Regardless of which assembly method you’re using to build products, the last thing you want is to let a customer down—either through stockouts or poorly manufactured products.

Assembling to order might not be the best strategy to use year-round. Use demand forecasting to identify busy seasons (like Black Friday Cyber Monday). Consider blending ATO with made-to-stock production to deliver seamless customer experiences at scale during that time.

Benefits of ATO in Manufacturing

Customizable products

Assembling a product when a customer orders gives you greater flexibility. You can take each individual customer's specifications into account and build customized products for which they’d pay up to 20% extra.

Lower carrying costs

Inventory storage is costing your business. A pile of unsold inventory that shows no sign of being sold anytime soon means you have cash tied up. Carrying surplus inventory also takes up space that could house your best-selling stock. This space is already precious; the cost of inventory storage is increasing rapidly each year.

Avoid dead stock

The assemble-to-order method helps manage supply chain operations to prevent dead stock since you only assemble products when they’ve been ordered. It’s easier to store and organize these raw materials (which could be repurposed, at a push, if demand isn’t there) than final products. Plus, if you’re selling perishable goods, the ATO strategy means you don’t run the risk of inventory spoiling or passing its expiry date. It makes more sense to stock unpeeled fruits and assemble a smoothie when a customer orders than to keep it refrigerated for an unspecified amount of time.

Disadvantages of ATO

Higher risk of stockouts

Stockouts happen when stock levels don’t meet customer demand. It’s one of the worst experiences you can give a customer. We’re conditioned to see, buy, and receive products from a retail store all within the same day.

Poor ATO management can lead to inventory management issues. Stockouts, already a $1 trillion problem for retailers, are exacerbated by poor demand forecasting. If you experience a surge in demand and you’re unable to assemble fast enough, it can result in low (or no) supply of inventory.

Longer lead times

Speed is of the essence for many retail customers. They want products in their hands in as little time as possible. But by the time they’ve completed an in-store purchase, an ATO product still hasn’t been assembled, making it impossible for them to take it home instantly. Granted, you can speed up these lead times with strong supply chain management. But even the smallest of delays still deter shoppers from making a purchase.

Potential for lower quality products

If you’re using the ATO method and still trying to meet speedy customer expectations, the assembly or manufacturing process can be rushed, resulting in a lower-quality final product. This can wreak havoc with customer retention and risk your store’s reputation.

Examples of Assemble-to-Order Production

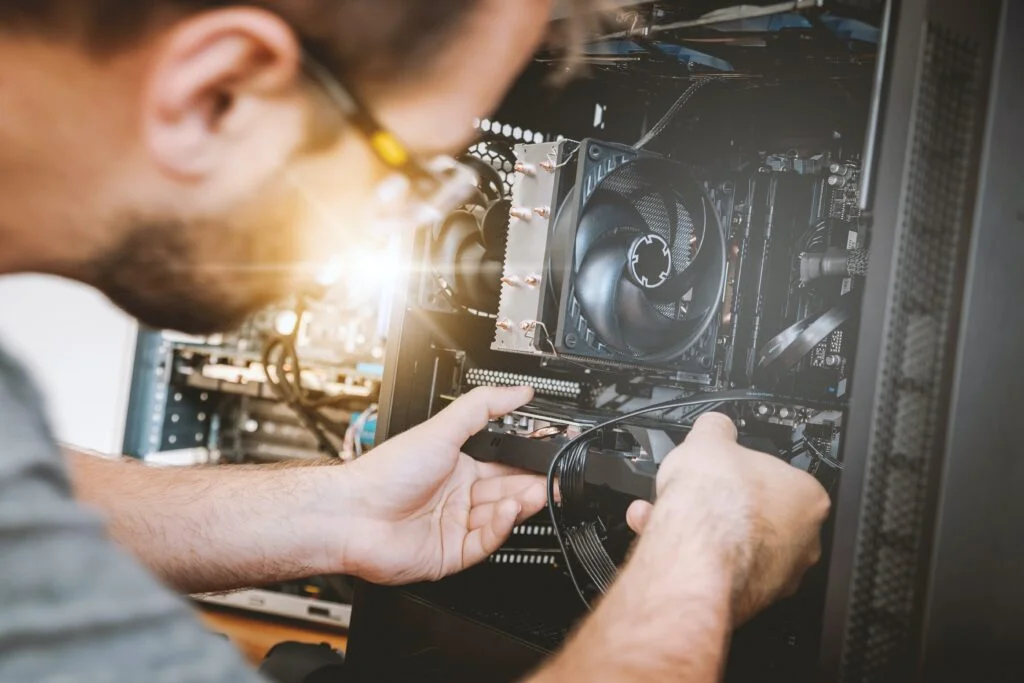

Imagine a computer company that uses the assemble-to-order (ATO) approach. They offer different options for memory, storage, graphics cards.

When a customer wants to buy a computer, they choose the features they want, like more memory or a better graphics card. The company keeps all the computer parts in its inventory, like screens, keyboards, and motherboards. But they don't fully put the computer together until an order comes in. Once a customer places an order, the company picks the right parts from their storage. For example, if a customer wants a computer with more memory and a faster graphics card, the company will buy those parts. They assemble the computer with these specific features and then ship it to the customer.

This approach helps the company because they don't need to predict which specific computers customers will buy. They only put things together when they know what each customer wants. It also helps them avoid keeping too many finished computers in storage.

READ MORE: